Forget about traditional transformer based measurement techniques!

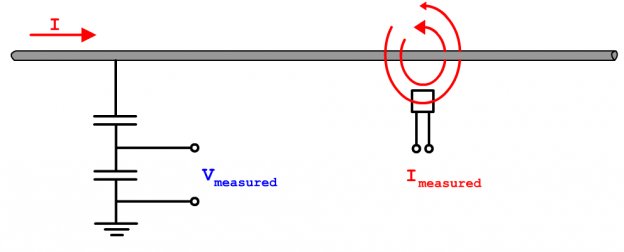

For substation automation purposes, the use of capacitors for voltage measurements and semiconductors for magnetic field (current measurements) offer significant advantages.

Voltage

By using the principle of capacitive voltage division, very accurate and wideband measurements are made possible. The high voltage side capacitor may be directly connected to voltages up to more than 100kV or via the distribution transformer low voltage side depending on the use case. Key parameters for quality measurements such as phase and frequency harmonics can be measured with higher accuaracy than what is possible with most voltage transformer solutions, and at a significantly reduced cost both in terms of space requirements, cost of the full sensor system, as well as installation costs.

Field installation of an I3 Power Sensor under a switch gear. The impossible three phase current measurement is thereby made possible. The black cables in the bottom on the sensor are voltage measurements.

Current

All currents generate a magnetic field. Magnetic fields can be measured accurately with semiconductor sensors the size of a fingernail. When several current conductors are closely spaced (e.g. in 3 or 4 conductor MV cables), more sensors are needed. Based on Jomitek proprietary technology, the position and exact amount of current flowing through the individual conductors at a given instant of time is determined on the fly.

Efficient data processing and transmission

When the exact currents and voltages are known – power, reactive power, energy direction and harmonics is calculated and stored locally on the fly. This allows for low bandwidth high level/high value data to be fed back to the SCADA. With this approach, bandwidths in the IoT (Internet of Things) domain of 10-100kbps becomes sufficent to ensure a continuous detailed monitoring, with a total data payload in the area of 1-100MB per month per device, depending on the use case. At the same time this ensures backhaul / transmission of data back to the SCADA to be within coverage of commercial cellular networks employing NB-IoT or LTE-M, where existing cellular network technologies does not reach.

Go to the I3 product page for detailed information.